Hydraulic Press Brake

Hydraulic Press Brake Specification

- Usage

- bend and form sheet metal

- Voltage

- 440 Volt (v)

- Capacity

- 30 Ton

- Product Type

- Hydraulic Press Brake

- Power

- 440 Volt (v)

- Weight

- 2000 Kilograms (kg)

- Machine Type

- automotive, aerospace, construction, and appliance manufacturing.

- Phase

- 3 phase

Hydraulic Press Brake Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 20 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

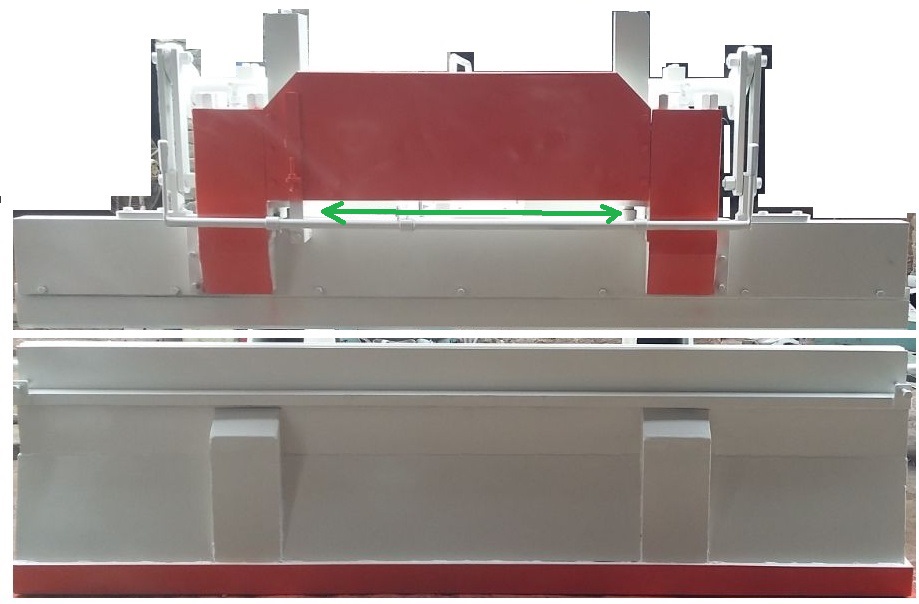

About Hydraulic Press Brake

A Hydraulic Press Brake is a powerful and precise machine used to bend and form sheet metal into custom angles and shapes using hydraulic force. It's a cornerstone in metal fabrication, commonly used in industries such as automotive, aerospace, construction, and appliance manufacturing.

What It Does:

It uses hydraulic cylinders to move a punch down onto a die, with the metal sheet placed in between. This creates sharp or curved bends in the sheet metal.

Key Components:

-

Ram (Upper Beam) Moves vertically using hydraulic power.

-

Punch The top tool that presses into the sheet.

-

Die The bottom tool that the punch forces the sheet into.

-

Hydraulic Cylinders Provide the force to operate the ram.

-

Bed (Lower Beam) Fixed base where the die is mounted.

-

Back Gauge Automatically positions the sheet for accuracy.

-

CNC Controller (optional) For programmable, precise control.

-

Frame Rigid structure that holds all parts in alignment.

Working Principle:

-

The sheet metal is placed on the die.

-

The hydraulic ram drives the punch down with high pressure.

-

The metal bends into the shape of the die cavity.

-

The angle and depth of the bend are controlled by the punch stroke and tooling setup.

Typical Specifications:

| Feature | Range |

|---|---|

| Bending Capacity | 20 1000+ tons |

| Bending Length | 1250 mm 6000+ mm |

| Stroke Length | 100 mm 300+ mm |

| Sheet Thickness Range | 1 mm 25+ mm |

| Control Types | Manual, NC, CNC |

Advantages:

-

Can bend thick and hard materials with ease.

-

Highly accurate and repeatable.

-

Suitable for complex bends and mass production.

-

CNC models allow for automation and high productivity.

-

Versatile works with a variety of dies and punches.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plate Bending Machine Category

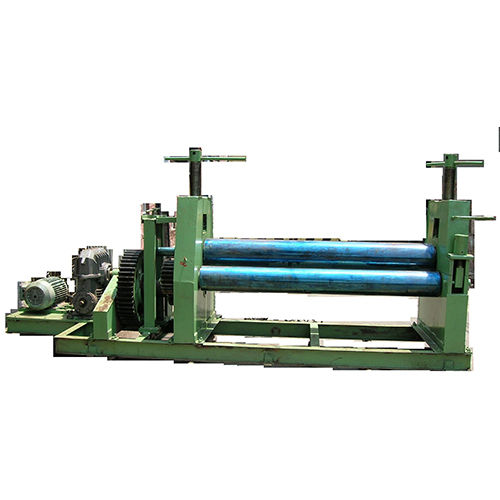

Sheet Roller Machine

Price 27000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : A sheet roller bends flat sheet metal by passing it between multiple rollers that apply pressure, forcing the sheet to curve gradually. You can roll full cylinders, cones, and curved panels depending on the machine and settings.

Product Type : Sheet Roller Machine

Automation : manual

Machine Type : Plate Rolling Machine or Sheet Bending Roller

Screw Type Sheet Bending Machine

Price 58800.0 INR / Number

Minimum Order Quantity : 1 Number

Usage : A screw type sheet bending machine uses a mechanical screw mechanism to apply pressure on a clamped sheet metal, forcing it to bend along a straight edge. It is ideal for making boxes, trays, panels, enclosures, and other fabricated sheet metal components.

Product Type : screw type sheet bending machine

Automation : Manual

Machine Type : mechanical screw mechanism

Plate Bending Machine

Price 800000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Plate Bending Machine

Automation : Automatic

Machine Type : Plate Bending Machine

Plate Bending Machine

Price 154000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Automation : Yes