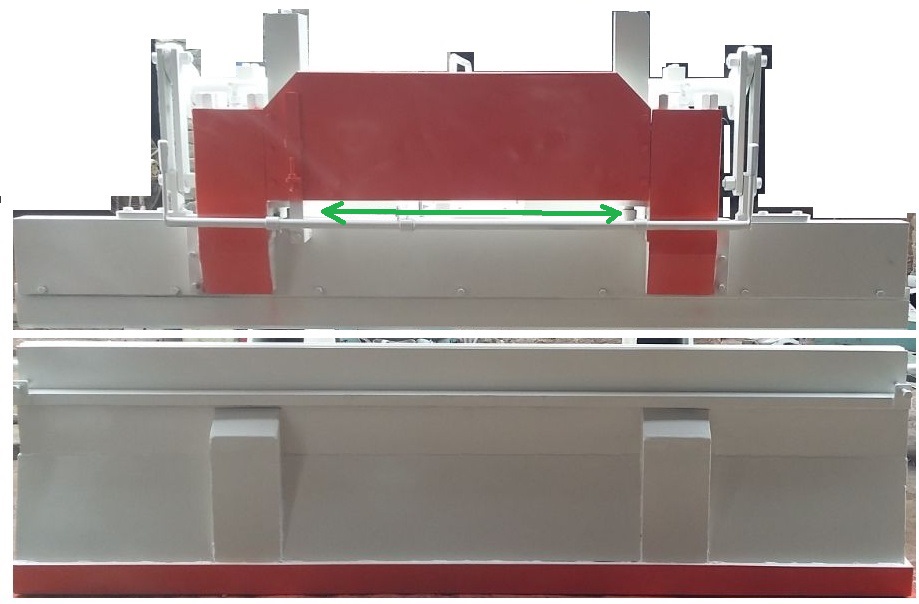

Sheet Roller Machine

Sheet Roller Machine Specification

- Usage

- A sheet roller bends flat sheet metal by passing it between multiple rollers that apply pressure, forcing the sheet to curve gradually. You can roll full cylinders, cones, and curved panels depending on the machine and settings.

- Weight

- 80 Kilograms (kg)

- Dimension (L*W*H)

- 52 Inch (in)

- Product Type

- Sheet Roller Machine

- Automation

- manual

- Machine Type

- Plate Rolling Machine or Sheet Bending Roller

Sheet Roller Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 20 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Sheet Roller Machine

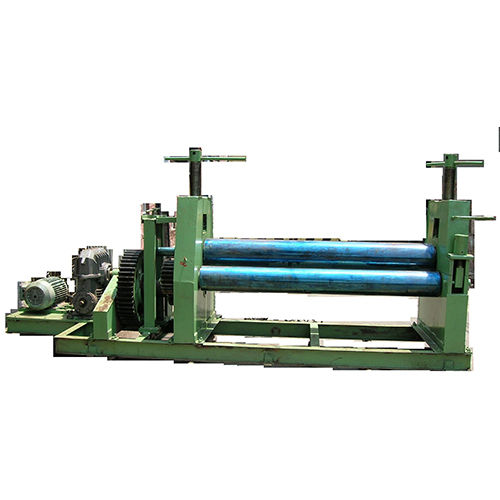

A Sheet Roller Machine (also known as a Plate Rolling Machine or Sheet Bending Roller) is used to roll sheet metal into cylindrical or conical shapes. It is widely used in metal fabrication, ducting, boiler making, tank manufacturing, and automotive industries.

What It Does:

A sheet roller bends flat sheet metal by passing it between multiple rollers that apply pressure, forcing the sheet to curve gradually. You can roll full cylinders, cones, and curved panels depending on the machine and settings.

Types of Sheet Roller Machines:

| Type | Description |

|---|---|

| 3-Roller Machine | Most common. Has 2 bottom rollers and 1 top roller. |

| 4-Roller Machine | Easier pre-bending, better accuracy, and control. Used for thicker plates. |

| Manual Rolling Machine | Operated by handwheel, ideal for thin sheets (0.52 mm). |

| Motorized (Electric or Hydraulic) | Used for thick sheets or industrial use. |

Working Principle:

-

Load the sheet between the rollers.

-

Clamp it with the top roller.

-

Rotate the rollers (manual or motorized) to pull and roll the sheet.

-

Adjust roller position to control the radius of the bend.

Typical Specifications:

| Feature | Range |

|---|---|

| Rolling Thickness | 0.5 mm 25 mm (depending on machine size/type) |

| Rolling Width | 1000 mm 3000 mm or more |

| Roller Material | Hardened steel or alloy steel |

| Drive System | Manual / Electric / Hydraulic |

| Output Shape | Cylindrical / Conical |

Advantages:

-

Can make round, oval, or conical shapes

-

Handles long sheets efficiently

-

Repeatable results

-

Low maintenance (especially manual versions)

Limitations:

-

Can't make sharp-angle bends (use press brake for that)

-

Conical rolling needs special roller alignment

-

Large/thick plate machines are expensive and heavy

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plate Bending Machine Category

Hydraulic Press Brake

Price 350000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : bend and form sheet metal

Product Type : Hydraulic Press Brake

Machine Type : automotive, aerospace, construction, and appliance manufacturing.

Screw Type Sheet Bending Machine

Price 58800.0 INR / Number

Minimum Order Quantity : 1 Number

Usage : A screw type sheet bending machine uses a mechanical screw mechanism to apply pressure on a clamped sheet metal, forcing it to bend along a straight edge. It is ideal for making boxes, trays, panels, enclosures, and other fabricated sheet metal components.

Product Type : screw type sheet bending machine

Machine Type : mechanical screw mechanism

Automation : Manual

Plate Bending Machine

Price 800000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Plate Bending Machine

Machine Type : Plate Bending Machine

Automation : Automatic

Plate Bending Machine

Price 154000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Automation : Yes